Our Vision

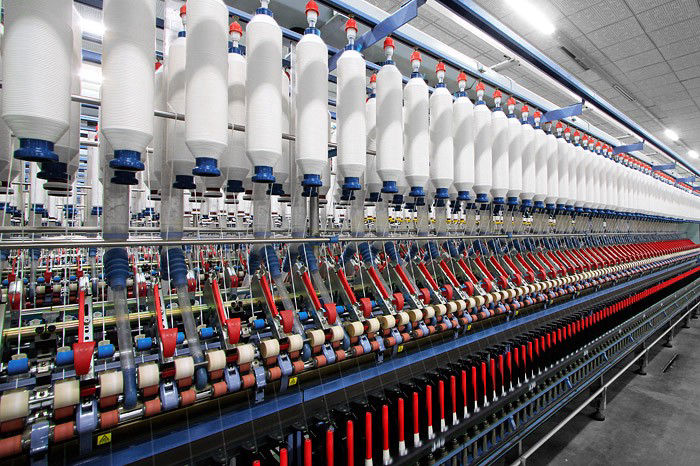

To create products with the best quality and consistency, continuing to win and retain the confidence & loyalty of our customers through innovation and on time delivery, by taking our achievements not as a resting stone but as a reminder of the customer’s confidence in us.

To Endeavour and meet the increasing challenge of supplying quality yarns consistently as desired

bycustomers of varied requirements based on highly variable raw material as cotton.